Developed internationally

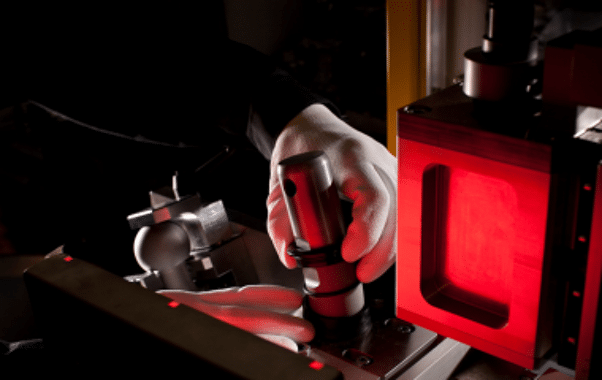

We are proud of the fact that we design, test and manufacture all our towbars in our own state-of-the-art production facilities in The Netherlands, France, South Africa and Thailand. All our towbars are developed for local conditions, and engineered by our global engineering teams. We are driven to deliver our standard of high quality in everthing that we do, proved by official certificates like IATF 16949, ISO 14001 and ISO 9001.